Die making is a complex process that involves designing and manufacturing metal dies used in various industries such as automotive, aerospace, and consumer goods. The die making process is crucial in the production of high-quality products, as it enables the mass production of identical parts with precise dimensions and specifications. In this article, we will explore the die making process from design to production, highlighting the key stages involved and the importance of each step.

Design Stage: Creating the Blueprint

The die making process begins with the design stage, where engineers and designers create a blueprint of the die using computer-aided design (CAD) software. The design must take into account the specific requirements of the product, including its shape, size, material, and functionality. The designers use 2D and 3D modeling techniques to create a detailed and accurate design, which is then reviewed and approved by the client. The design stage is critical, as any errors or inaccuracies can lead to costly revisions or even render the die unusable.

Material Selection and Procurement

Once the design is finalized, the next step is to select the appropriate materials for the die. The choice of material depends on the product’s requirements, such as durability, corrosion resistance, and thermal conductivity. Common materials used in die making include steel, aluminum, and copper. The selected materials are then procured from suppliers, and the die maker must ensure that the materials meet the required specifications and standards.

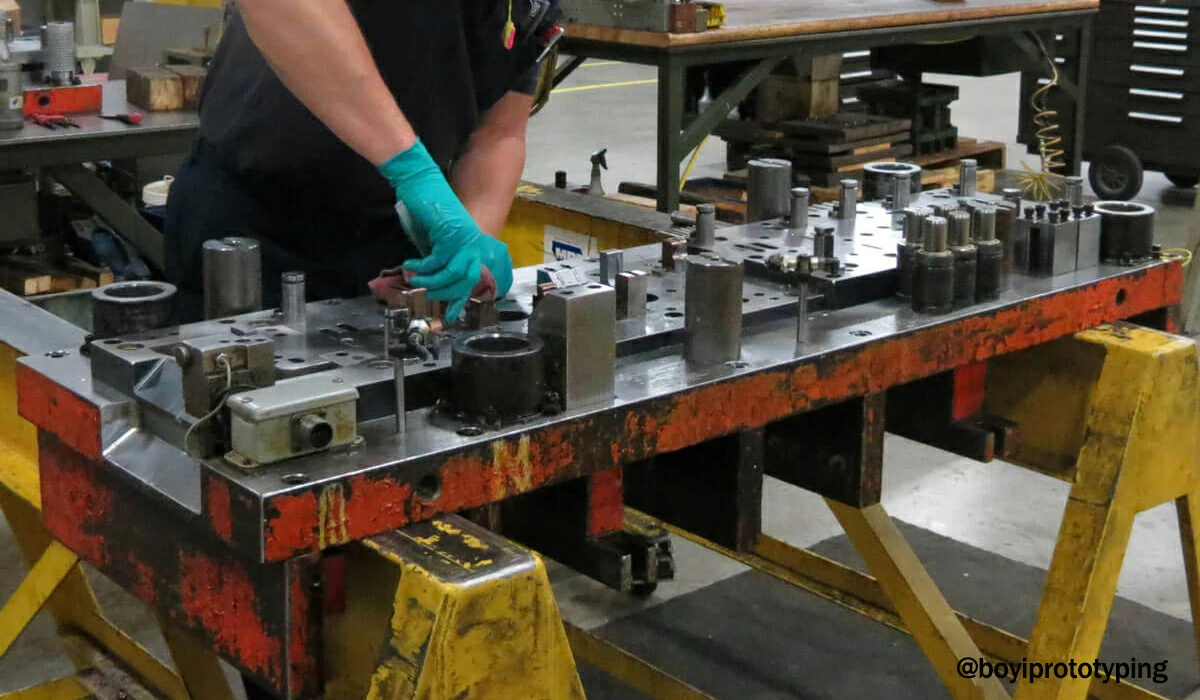

Machining and Tooling

The machining and tooling stage is where the raw materials are transformed into the desired shape and form. The die maker uses various machining techniques, such as milling, turning, and grinding, to create the die’s components. The tooling process involves creating the necessary tools and fixtures to support the die during production. This stage requires high precision and accuracy, as any errors can affect the die’s performance and longevity.

Heat Treatment and Finishing

After machining and tooling, the die undergoes heat treatment to enhance its mechanical properties. Heat treatment involves heating the die to a specific temperature and then cooling it to achieve the desired level of hardness and toughness. The die is then subjected to various finishing processes, such as polishing and coating, to improve its surface quality and reduce wear and tear.

Assembly and Testing

The final stage of the die making process is assembly and testing. The die’s components are assembled, and the die is tested to ensure that it meets the required specifications and standards. The testing process involves checking the die’s accuracy, precision, and performance under various conditions. Any defects or issues are addressed, and the die is refined until it meets the desired quality standards.

Production and Maintenance

Once the die is tested and validated, it is ready for production. The die is used to manufacture the desired products, and the die maker must ensure that the die is properly maintained to extend its lifespan. Regular maintenance involves cleaning, lubricating, and inspecting the die to prevent wear and tear. The die maker must also keep records of the die’s performance and make any necessary adjustments to maintain its accuracy and precision.

Conclusion

The die making process is a complex and precise process that requires careful planning, design, and execution. From design to production, each stage of the process is critical in ensuring the quality and accuracy of the final product. By understanding the die making process, manufacturers can appreciate the importance of investing in high-quality dies that meet their specific needs and requirements. Whether it’s for automotive, aerospace, or consumer goods, the die making process plays a vital role in the production of high-quality products that meet the demands of modern industries.