Ultraviolet (UV) diodes have become increasingly important in various applications, including disinfection, curing, and spectroscopy. High-performance UV LED diode are in high demand, but their manufacturing poses significant challenges. In this article, we will explore the challenges faced by manufacturers in producing high-performance UV diodes and discuss the factors that contribute to these challenges.

Material Selection and Quality

One of the primary challenges in manufacturing high-performance UV diodes is the selection and quality of materials. UV diodes require high-quality semiconductor materials with precise control over their composition and structure. The most commonly used materials for UV diodes are gallium nitride (GaN) and aluminum gallium nitride (AlGaN), which are difficult to grow and process. The quality of these materials can significantly impact the performance and reliability of the UV diode, making it essential to control defects, impurities, and uniformity.

Epitaxial Growth and Doping

Epitaxial growth and doping are critical steps in the manufacturing of UV diodes. The epitaxial growth process involves depositing thin layers of semiconductor material on a substrate, which requires precise control over temperature, pressure, and gas flow. Doping involves introducing impurities into the semiconductor material to control its electrical properties. However, doping can be challenging, especially for UV diodes, which require precise control over the doping concentration and profile. Any errors in the epitaxial growth or doping process can lead to defects, which can significantly impact the performance of the UV diode.

Device Fabrication and Processing

Device fabrication and processing are also critical steps in the manufacturing of UV diodes. The fabrication process involves creating the diode structure, including the anode and cathode, and the processing steps, such as etching and metallization. However, the fabrication and processing of UV diodes can be challenging due to the small size and complex structure of the devices. Any errors in the fabrication or processing steps can lead to defects, which can impact the performance and reliability of the UV diode.

Thermal Management

Thermal management is another significant challenge in the manufacturing of high-performance UV diodes. UV diodes generate a significant amount of heat during operation, which can impact their performance and reliability. Effective thermal management is essential to ensure that the UV diode operates within a safe temperature range. However, thermal management can be challenging, especially for high-power UV diodes, which require sophisticated cooling systems to manage the heat generated.

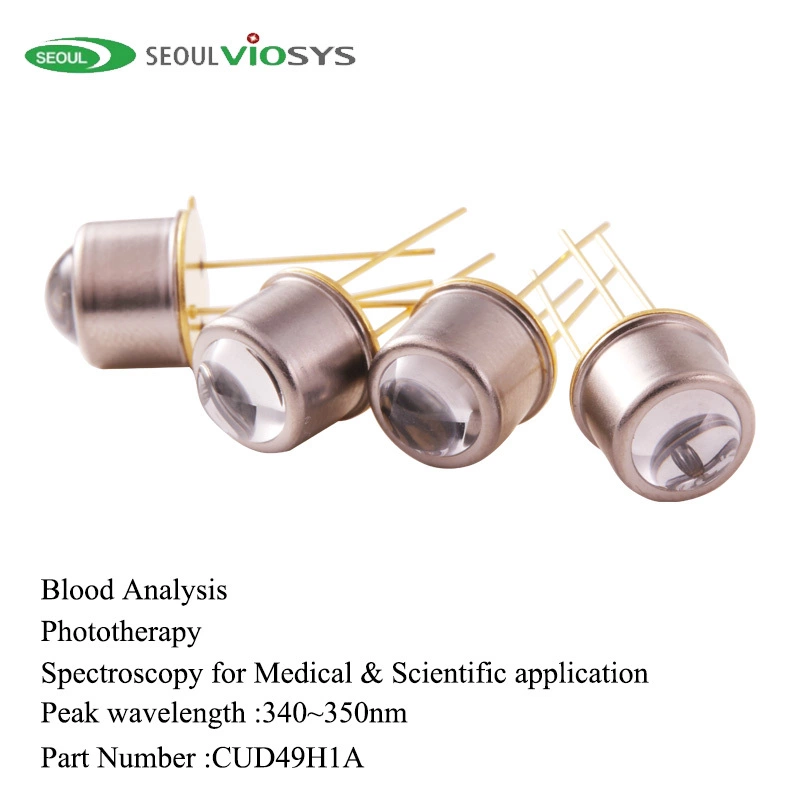

Packaging and Reliability

Packaging and reliability are also critical challenges in the manufacturing of high-performance UV diodes. The packaging process involves encapsulating the UV diode in a protective material, such as a ceramic or plastic package, to protect it from environmental stressors. However, the packaging process can be challenging, especially for UV diodes, which require specialized packaging materials and designs to ensure reliable operation. Reliability is also a significant concern, as UV diodes are often used in applications where failure can have significant consequences.

Future Directions and Opportunities

Despite the challenges, researchers and manufacturers are exploring new technologies and techniques to improve the performance and reliability of UV diodes. For example, the use of advanced materials, such as graphene and nanowires, is being explored for UV diode applications. Additionally, new manufacturing techniques, such as 3D printing and nanoimprint lithography, are being developed to improve the fabrication and processing of UV diodes. These advances offer significant opportunities for the development of high-performance UV diodes with improved efficiency, reliability, and cost-effectiveness.

Conclusion

In conclusion, the manufacturing of high-performance UV diodes poses significant challenges, including material selection and quality, epitaxial growth and doping, device fabrication and processing, thermal management, packaging, and reliability. However, researchers and manufacturers are exploring new technologies and techniques to overcome these challenges and improve the performance and reliability of UV diodes. As the demand for high-performance UV diodes continues to grow, it is essential to address these challenges and develop new solutions to ensure the continued advancement of UV diode technology.