Insert and overmolding services play a crucial role in maximizing efficiency in product manufacturing. These services offer a cost-effective and time-saving solution for integrating different components into a single, cohesive product. By combining multiple parts into one, manufacturers can streamline production processes, reduce assembly time, and ultimately save on costs.

Benefits of Insert and Overmolding Services

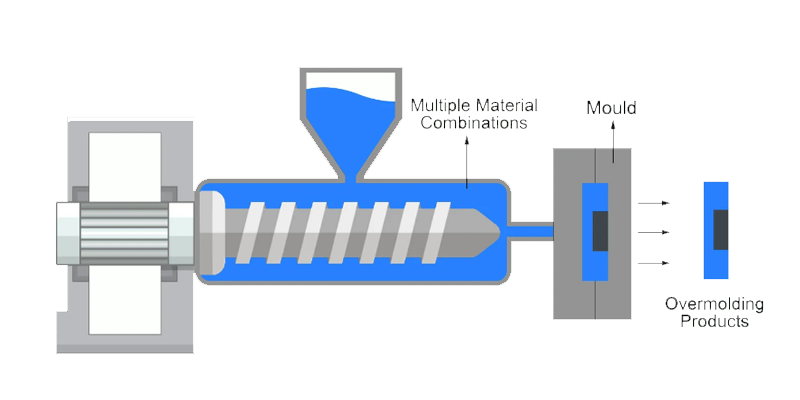

One of the key benefits of insert and overmolding services is the ability to create complex products with multiple components in one single process. This eliminates the need for separate steps in assembly and reduces the risk of errors or defects during production. By encapsulating various components within a single mold, manufacturers can ensure a precise and secure fit, leading to a higher quality end product.

Enhancing Product Durability and Functionality

Moreover, insert and overmolding services can also enhance the overall durability and functionality of a product. By securely bonding different materials together, manufacturers can create products that are more resistant to wear and tear, environmental factors, and other potentially damaging conditions. This can extend the lifespan of a product and improve its performance, ultimately leading to greater customer satisfaction and loyalty.

Efficiency Gains in Production

In addition to improving product quality, insert and overmolding services also offer efficiency gains in the production process. By eliminating the need for separate assembly steps, manufacturers can reduce lead times, minimize labor costs, and optimize their overall production schedules. This can result in faster time-to-market for new products and a quicker response to changing market demands.

Reducing Waste and Promoting Sustainability

Furthermore, insert and overmolding services can also help manufacturers reduce waste and minimize their environmental impact. By creating products with fewer components and less material usage, manufacturers can lower their carbon footprint and promote sustainability in their operations. This can be particularly important for companies looking to improve their corporate social responsibility and meet the growing demands for eco-friendly products.

Conclusion

Overall, insert and overmolding services offer a wide range of benefits for manufacturers looking to maximize efficiency in their product manufacturing processes. By integrating multiple components into a single, cohesive product, manufacturers can streamline production, improve product quality, and reduce costs. These services also offer the flexibility to create complex products with diverse materials, leading to enhanced durability and functionality.